-

Extrusion molding of plastic profile manufacturers

2020-12-17 1124

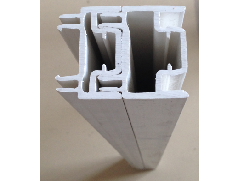

Plastic profile extrusion molding planning considerations. In the planning of extrusion molding of plastic profile, special attention should be paid to the uniformity of wall thickness, fillet and stiffener. If there is any omission, it will lead to irreparable defects. Li, chief engineer of the plastic molding Research Institute of Tsinghua University, also pointed out that the planning of plastic products is very different with different cooling and setting methods. Let's take a look at the th

-

Influence of technical commonness on PVC profile manufacturers

2020-12-17 1202

The coextrusion of PVC profiles and multicolored surface layers is one of the most popular coloration methods for PVC profiles in China. From 2002 to now, the development trend of producing colorful profiles by CO extrusion is rapid, accounting for about 40% of the sales market of colorful profiles, and it is estimated to reach 80% in 2020. By using coextrusion technology, the milky white PVC profile can be colored, and the aging resistance, temperature resistance and impact resistance of the PV

-

Coloring problems of PVC profile manufacturers

2020-12-17 1173

Therefore, in terms of PVC coloring, fully consider the characteristics of commonly used resins and related modifiers, and blend the characteristics of color paste. In the selection of additives, we should pay attention to the following three problems: 1. Production and processing reliability, some ingredients in additives will promote the dissolution of resin. For example, iron ion and zinc ion are metal catalysts for PVC resin dissolution. Therefore, the use of compound (red, yellow, brown and

-

Analysis on the defects of PVC profile manufacturer's production process

2020-12-17 1184

PVC profiles are widely used and bring convenience to our life. Generally, when we choose PVC profile, we will go to the regular business to buy, this posture quality is more guaranteed. We should read the operation manual carefully before using PVC profile, so that there will be no problem in the application process, which will affect our work. Some time, due to our improper use of methods will form PVC profile can not be used normally, then what should we do? 1. Surface tarnish: causes: poor p

-

PVC profile manufacturers talk about the causes of cracks

2020-12-17 1060

PVC profile bubble. Cracks and pockmarks (1) the main reasons for the above are as follows: 1) the moisture and volatile substances contained in various materials are seriously overspended, and can not be fully swept out in the extrusion mixing process, and the volatiles are still retained in the material, and bubbles, cracks and pockmarks will appear inside or outside the profile after heating. Once this kind of phenomenon appears in production, the influence of raw materials should be eliminat

-

Let PVC profile manufacturer answer profile and profile for you

2020-12-17 1033

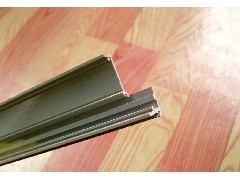

Can you distinguish PVC profiles from profiles? I believe that many people or people who have just come into contact with aluminum profiles are always confused about profile and profile, and can't make out the difference between the two. Today, Xiaobian explained the difference between the two profiles to the silly friends. Extrudate: it is an object with certain geometric shape made of iron or steel and materials with certain strength and durability (such as plastic, aluminum, glass fiber, etc.

-

PVC profile manufacturers tell you the choice of formula

2020-12-17 1001

In the production of SG-5 resin with low polymerization degree, the selection and formulation of PVC materials should be selected. The higher the degree of polymerization, the better the physical and mechanical properties and heat resistance. However, the poor fluidity of the resin leads to certain difficulties in processing. Therefore, SG-5 resin with viscosity of (1.7 ~ 1.8) × 10-3 Pa? S should be selected. Lead stabilizer is generally used for hard tube, which has good thermal stability and i

-

Application and maintenance of plastic profile

2020-12-17 1094

Application and maintenance: 1. Check the plastic profile extrusion mold after arrival, open the box to check, the package is intact: after unpacking, take out the packing list, use the manual and other skills documents, organize and count the whole mold, accessories and special tools according to the contents of the packing list. 2. Half skill requirements and status of plastic profile extrusion die, especially when the extrusion material is modified polyethylene, its molding parts are generall

-

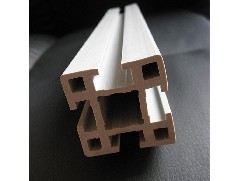

This paper introduces the manufacturers and uses of plastic profiles

2020-12-17 1059

Introduction to plastic profiles: plastic profiles are listed as one of the building materials in China due to their excellent thermal insulation performance. In the production process of plastic profile, what problems should be paid attention to to to ensure the quality and process of profile. Application of plastic profile: plastic profile products are widely used: window frame, stair handrail, raceway, skirting board, special-shaped pipe, etc. The raw materials are mainly hard PVC, a few are

-

Material advantages of plastic profile manufacturers

2020-12-17 1022

Advantages of plastic profiles: 1. Thermal stabilizers: plastic profiles are thermosensitive plastics, so in the production and processing of plastic profiles, thermal stabilizers are essential. The metal salt in the thermal stability agent can absorb HCl decomposed from PVC, so it can delay the decomposition speed of plastics and extend the decomposition time. Compound lead salts are used in the production of plastic profiles, which have high thermal stability efficiency and low price. 2. Lubri