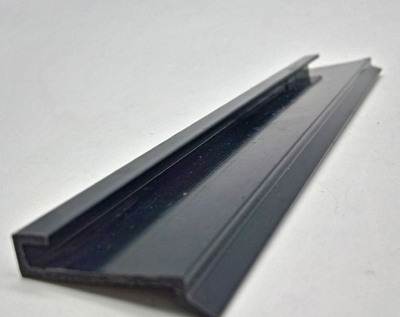

PVC profile manufacturers talk about the causes of cracks

PVC profile bubble. Cracks and pockmarks

(1) the main causes of the above are as follows:

1) the moisture and volatile matter contained in various materials are seriously overspended, and can not be fully swept away in the extrusion mixing process. The volatiles are still kept in the interior of the materials, and bubbles, cracks and pockmarks will appear on the inside or outside of the profiles after heating. Once this kind of phenomenon appears in production, the influence of raw materials should be eliminated first, and then the reasonable process conditions should be worked out in high-speed mixing, which can sweep away the volatiles.

2) PVC is a kind of thermosensitive plastics with poor thermal stability. Although there are some thermosetting agents in the formulation, such as poor stabilizer or overheating and differentiation due to the disadvantages of extrusion process, the hydrogen evolution gas generated can not be fully discharged and stay in the material, and there will be fine small pores on the profile section or internal and external surfaces. The occurrence of such pores is related to the extrusion of the heating system of the extruder The control ability of outlet temperature is related to uniformity. The extrusion temperature should not be too high, otherwise it is easy to plasticize and produce too much gas remaining in the profile and even crack. If the extrusion temperature is too low, the material will be plasticized, and the unplasticized particles will make the profile surface pitted, burred and rough. Adjusting the correct process temperature is the key to control the material plasticization. In the process of extrusion, the heat mainly comes from external heat source and shearing conflict heat. At the beginning of start-up, the heat mainly comes from external heating. After startup, the shear conflict heat increases continuously, sometimes even exceeding the heat required by the material. Therefore, the heat should be dissipated through the system to avoid thermal differentiation. Therefore, the heating system of extruder should be able to ensure stable extrusion temperature and precise control High degree. The shearing conflict heat is related to screw speed, nose pressure and so on. Adjusting the screw speed and head pressure in production to make the shearing conflict heat reasonable, can to a certain extent, heat up the running conditions of the system.

3) the occurrence of bubbles is also related to the function of exhaust system of extruder. The function of the twin-screw is divided into four areas: feeding area, compression area, exhaust area and homogenization area. The pressure from the feeding area to the compression area is gradually, and the pressure in the exhaust area drops sharply, while the pressure in the homogenization area rises rapidly. In the exhaust zone, the vaporized volatiles simply escape from the melt due to pressure drop, and are discharged from the exhaust port at the vacuum degree of not less than 0.05Mpa. In addition, the feed rate and extrusion volume of extruder should be balanced. When the feed rate is greater than the extrusion amount, the excess material will be continuously squeezed to the low pressure vent under the effect of pressure, resulting in the material coming out from the vent hole, or even blocking the exhaust hole, thus losing the exhaust function.

Source: PVC profile manufacturer www.zhongshanlida.cn

-

12-17

Extrusion molding of plastic profile manufacturers

Plastic profile extrusion molding planning considerations. In the planning of extrusion molding of plastic profile, special attention should be paid to the uniformity of wall thickness, fillet and stiffener. If there is any omission, it will lead to irreparable defects. Li, chief engineer of the plastic molding Research Institute of Tsinghua University, also pointed out that the planning of plastic products is very different with different cooling and setting methods. Let's take a look at the th

-

12-17

Influence of technical commonness on PVC profile manufacturers

The coextrusion of PVC profiles and multicolored surface layers is one of the most popular coloration methods for PVC profiles in China. From 2002 to now, the development trend of producing colorful profiles by CO extrusion is rapid, accounting for about 40% of the sales market of colorful profiles, and it is estimated to reach 80% in 2020. By using coextrusion technology, the milky white PVC profile can be colored, and the aging resistance, temperature resistance and impact resistance of the PV

-

12-17

Coloring problems of PVC profile manufacturers

Therefore, in terms of PVC coloring, fully consider the characteristics of commonly used resins and related modifiers, and blend the characteristics of color paste. In the selection of additives, we should pay attention to the following three problems: 1. Production and processing reliability, some ingredients in additives will promote the dissolution of resin. For example, iron ion and zinc ion are metal catalysts for PVC resin dissolution. Therefore, the use of compound (red, yellow, brown and

-

12-17

Analysis on the defects of PVC profile manufacturer's production process

PVC profiles are widely used and bring convenience to our life. Generally, when we choose PVC profile, we will go to the regular business to buy, this posture quality is more guaranteed. We should read the operation manual carefully before using PVC profile, so that there will be no problem in the application process, which will affect our work. Some time, due to our improper use of methods will form PVC profile can not be used normally, then what should we do? 1. Surface tarnish: causes: poor p