Plastic profile manufacturers talk about crystallization reasons

Plastic profile is a very common product in our production, so let's talk about the reasons that affect the crystallization of thermoplastic plastics

1. Thermoplastics can be divided into crystalline plastics and amorphous plastics according to the fact that there is no crystallization during condensation.

The so-called crystallization phenomenon refers to the phenomenon that the molecules move independently and are completely in a disordered state from the melting state to the condensation state, and the molecules stop their free movement, press a slightly fixed position, and there is a tendency to make the molecular placement a regular model.

2. As a criterion for judging the appearance of these two types of plastics, it can be determined by the transparency of thick wall plastic parts. Generally, crystalline materials are opaque or semi transparent (such as POM) and amorphous materials are transparent (such as PMMA). But there are also exceptions, such as poly (tetramethylene) is a crystalline plastic with high transparency, ABS is amorphous but not transparent.

3. In mold design and selection of injection molding machine, attention should be paid to the amount of heat required for the material temperature to rise to the molding temperature, and the equipment with large plasticizing capacity should be used.

Source: plastic profile manufacturer www.zhongshanlida.cn

-

12-17

Extrusion molding of plastic profile manufacturers

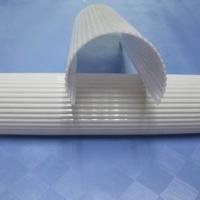

Plastic profile extrusion molding planning considerations. In the planning of extrusion molding of plastic profile, special attention should be paid to the uniformity of wall thickness, fillet and stiffener. If there is any omission, it will lead to irreparable defects. Li, chief engineer of the plastic molding Research Institute of Tsinghua University, also pointed out that the planning of plastic products is very different with different cooling and setting methods. Let's take a look at the th

-

12-17

Influence of technical commonness on PVC profile manufacturers

The coextrusion of PVC profiles and multicolored surface layers is one of the most popular coloration methods for PVC profiles in China. From 2002 to now, the development trend of producing colorful profiles by CO extrusion is rapid, accounting for about 40% of the sales market of colorful profiles, and it is estimated to reach 80% in 2020. By using coextrusion technology, the milky white PVC profile can be colored, and the aging resistance, temperature resistance and impact resistance of the PV

-

12-17

Coloring problems of PVC profile manufacturers

Therefore, in terms of PVC coloring, fully consider the characteristics of commonly used resins and related modifiers, and blend the characteristics of color paste. In the selection of additives, we should pay attention to the following three problems: 1. Production and processing reliability, some ingredients in additives will promote the dissolution of resin. For example, iron ion and zinc ion are metal catalysts for PVC resin dissolution. Therefore, the use of compound (red, yellow, brown and

-

12-17

Analysis on the defects of PVC profile manufacturer's production process

PVC profiles are widely used and bring convenience to our life. Generally, when we choose PVC profile, we will go to the regular business to buy, this posture quality is more guaranteed. We should read the operation manual carefully before using PVC profile, so that there will be no problem in the application process, which will affect our work. Some time, due to our improper use of methods will form PVC profile can not be used normally, then what should we do? 1. Surface tarnish: causes: poor p